Earth Sustaining Symbiotic Biotechnology

Earth Sustaining Symbiotic Biotechnology

The Symbiotic Aquatic BioReactor process has the ability to treat all levels of acid mine drainage (AMD), extreme alkaline process drainage, and other metals and organic reagent contaminated waters and soils. SABR allows reduction of unwanted, sub-compliant and delinquent water volumes utilising tailored balanced system bio-cells to correct pH issues at all levels (0-14 pH) and remove contaminants; decreasing corruption of water, soil and the environment, thus reducing risk. SABR is scalable to any required size and throughput using simple and cost-effective open systems. In situations where space is at a premium or contaminants may be especially hazardous, SABR can be implemented in closed systems. Complex chemistries often result in a system where conditions appropriate to strip one class of contaminants are conducive to stabilisation of others in solution. SABR allows serial reactor implementation using different sets of bio-cells, such that consecutive manifolds can control all contaminants. SABR can rapidly, naturally and cost effectively treat AMD/ARD and process waters to a standard that allows their safe use or disposal on site, or discharge off site with negligible risk and within compliance requirements. SABR is designed for rapid implementation and ease oof activation, management and closure. Initial tailoring of the approach is through field lab-based wet chemistry, followed by small scale cost-effective on-site pilot reactors to determine a site-specific bio-tuning and demonstrate that the full-scale system will deliver appropriate results.

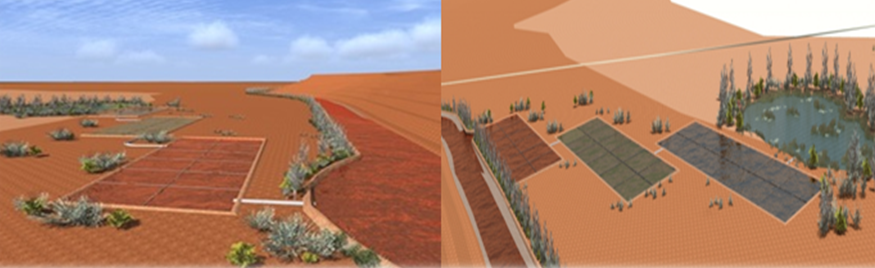

Engineered example of scalable open SABR systems

SABR is scalable to any required size and throughput using open systems. In situations where space is at a premium or contaminants may be especially hazardous, SABR can be implemented in closed systems. Complex chemistries often result in a system where conditions appropriate to strip one class of contaminants is conducive to stabilisation of others in solution. SABR allows serial reactor implementation using different sets of bio-cells, such that consecutive manifolds can control all contaminants. SABR can rapidly, naturally and cost effectively treat acidic and alkaline process affected soil and water, (0-14 pH) reducing metals, metalloid and other contaminants to a standard that allows their safe use, disposal on site, or discharge off site with negligible risk and within compliance requirements. SABR is simply and quickly implemented. Initial tailoring of the approach is through wet chemistry, and small-scale on-site pilot reactors to determine site specific biotuning and demonstrate the ability of a full-scale system. The bio-tuning process allows optimisation of the SABR system to site specific donor geology, commodity beneficiation processes, water chemistry and climate. Following more than 26-years’ of development and field proving, SABR has demonstrated effectiveness in waters associated with coal mines, gold mines, platinum mines, iron mines, phosphate refinery effluents, phosphogypsum effluents, acid refinery effluents, polymetallic rare earth element and radiogenic element bearing effluents, power station effluents, fly ash effluents, agriculture, and coal, gold, copper, zinc, lead, phosphate, poly metals, bauxite/alumina and iron ore tailings facilities. In all cases SABR delivered the solution. In all cases SABR enabled remediation of the disturbed ecology and rapid reinvigoration of riverine, riparian, lacustrine, wetland, littoral and soil systems.